kc_evenGapLaminar |

|

Information

This information is part of the Modelica Standard Library maintained by the Modelica Association.

Calculation of the mean convective heat transfer coefficient kc for a laminar fluid flow through an even gap at different fluid flow and heat transfer situations.

Functions kc_evenGapLaminar and kc_evenGapLaminar_KC

There are basically three differences:

- The function kc_evenGapLaminar is using kc_evenGapLaminar_KC but offers additional output variables like e.g. Reynolds number or Nusselt number and failure status (an output of 1 means that the function is not valid for the inputs).

- Generally the function kc_evenGapLaminar_KC is numerically best used for the calculation of the mean convective heat transfer coefficient kc at known mass flow rate.

- You can perform an inverse calculation from kc_evenGapLaminar_KC, where an unknown mass flow rate is calculated out of a given mean convective heat transfer coefficient kc

Restriction

- laminar regime (Reynolds number ≤ 2200)

- developed fluid flow

- heat transfer from one side of the gap (target=Modelica.Fluid.Dissipation.Utilities.Types.kc_evenGap.DevOne)

- heat transfer from both sides of the gap (target=Modelica.Fluid.Dissipation.Utilities.Types.kc_evenGap.DevBoth)

- undeveloped fluid flow

- heat transfer from one side of the gap (target=Modelica.Fluid.Dissipation.Utilities.Types.kc_evenGap.UndevOne)

- Prandtl number 0.1 ≤ Pr ≤ 10

- heat transfer from both sides of the gap (target=Modelica.Fluid.Dissipation.Utilities.Types.kc_evenGap.UndevBoth)

- Prandtl number 0.1 ≤ Pr ≤ 1000

- heat transfer from one side of the gap (target=Modelica.Fluid.Dissipation.Utilities.Types.kc_evenGap.UndevOne)

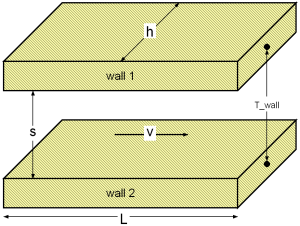

Geometry

Calculation

The mean convective heat transfer coefficient kc for an even gap is calculated through the corresponding Nusselt number Nu_lam according to [VDI 2002, p. Gb 7, eq. 43] :

Nu_lam = [(Nu_1)^3 + (Nu_2)^3 + (Nu_3)^3]^(1/3)

with the corresponding mean convective heat transfer coefficient kc :

kc = Nu_lam * lambda / d_hyd

with

| cp | as specific heat capacity at constant pressure [J/(kg.K)], |

| d_hyd = 2*s | as hydraulic diameter of gap [m], |

| eta | as dynamic viscosity of fluid [Pa.s], |

| h | as height of cross sectional area in gap [m], |

| kc | as mean convective heat transfer coefficient [W/(m2.K)], |

| lambda | as heat conductivity of fluid [W/(m.K)], |

| L | as overflowed length of gap (normal to cross sectional area) [m] , |

| Nu_lam | as mean Nusselt number [-], |

| Pr = eta*cp/lambda | as Prandtl number [-], |

| rho | as fluid density [kg/m3], |

| s | as distance between parallel plates of cross sectional area [m], |

| Re = rho*v*d_hyd/eta | as Reynolds number [-], |

| v | as mean velocity in gap [m/s]. |

The summands for the mean Nusselt number Nu_lam at a chosen fluid flow and heat transfer situation are calculated as follows:

- developed fluid flow

- heat transfer from one side of the gap (target=1)

- Nu_1 = 4.861

- Nu_2 = 1.841*(Re*Pr*d_hyd/L)^(1/3)

- Nu_3 = 0

- heat transfer from both sides of the gap (target=2)

- Nu_1 = 7.541

- Nu_2 = 1.841*(Re*Pr*d_hyd/L)^(1/3)

- Nu_3 = 0

- heat transfer from one side of the gap (target=1)

- undeveloped fluid flow

- heat transfer from one side of the gap (target=3)

- Nu_1 = 4.861

- Nu_2 = 1.841*(Re*Pr*d_hyd/L)^(1/3)

- Nu_3 = [2/(1+22*Pr)]^(1/6)*(Re*Pr*d_hyd/L)^(1/2)

- heat transfer from both sides of the gap (target=4)

- Nu_1 = 7.541

- Nu_2 = 1.841*(Re*Pr*d_hyd/L)^(1/3)

- Nu_3 = [2/(1+22*Pr)]^(1/6)*(Re*Pr*d_hyd/L)^(1/2)

- heat transfer from one side of the gap (target=3)

Note that the fluid properties shall be calculated with an arithmetic mean temperature out of the fluid flow temperatures at the entrance and the exit of the gap.

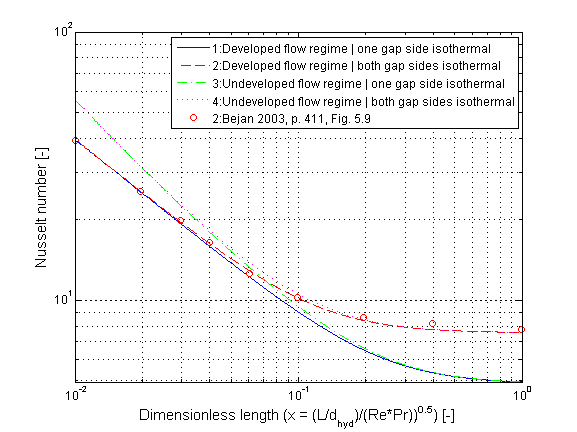

Verification

The mean Nusselt number Nu_lam representing the mean convective heat transfer coefficient kc in dependence of the chosen fluid flow and heat transfer situations (targets) is shown in the figure below.

References

- Bejan,A.:

- Heat transfer handbook. Wiley, 2003.

- VDI:

- VDI - Wärmeatlas: Berechnungsblätter für den Wärmeübergang. Springer Verlag, 9th edition, 2002.