Modelica.Mechanics.Rotational.UsersGuide

Modelica.Mechanics.Rotational.UsersGuide Modelica.Mechanics.Rotational.UsersGuide

Modelica.Mechanics.Rotational.UsersGuide

Library Rotational is a free Modelica package providing 1-dimensional, rotational mechanical components to model in a convenient way drive trains with frictional losses. More details are given in the following sub-sections:

Extends from Modelica.Icons.Information (Icon for general information packages).

| Name | Description |

|---|---|

| Overview | |

| Flange Connectors | |

| Support Torques | |

| Sign Conventions | |

| User Defined Components | |

| Requirements for Simulation Tools | |

| State Selection | |

| Modeling of Friction | |

| References | |

| Contact |

Modelica.Mechanics.Rotational.UsersGuide.Overview

Modelica.Mechanics.Rotational.UsersGuide.OverviewThis package contains components to model 1-dimensional rotational mechanical systems, including different types of gearboxes, shafts with inertia, external torques, spring/damper elements, frictional elements, backlash, elements to measure angle, angular velocity, angular acceleration and the cut-torque of a flange. In sublibrary Examples several examples are present to demonstrate the usage of the elements. Just open the corresponding example model and simulate the model according to the provided description.

A unique feature of this library is the component-oriented modeling of Coulomb friction elements, such as friction in bearings, clutches, brakes, and gear efficiency. Even (dynamically) coupled friction elements, e.g., as in automatic gearboxes, can be handled without introducing stiffness which leads to fast simulations. The underlying theory is new and is based on the solution of mixed continuous/discrete systems of equations, i.e., equations where the unknowns are of type Real, Integer or Boolean. Provided appropriate numerical algorithms for the solution of such types of systems are available in the simulation tool, the simulation of (dynamically) coupled friction elements of this library is efficient and reliable.

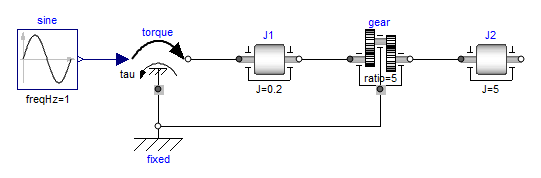

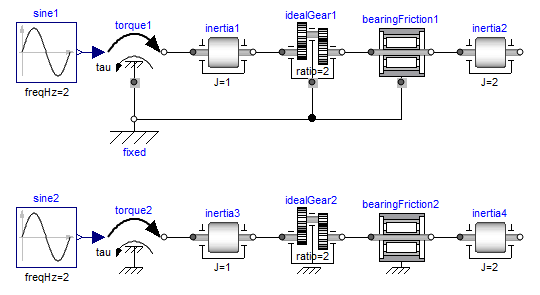

A simple example of the usage of this library is given in the

figure above. This drive consists of a shaft J1 with inertia

J = 0.2 kg.m2 which

is connected via an ideal gearbox with gear ratio = 5 to a second shaft J2

with inertia J = 5 kg.m2. The left shaft is driven via an external,

sinusoidal torque.

The filled and non-filled grey squares at the left and

right side of a component represent mechanical flanges.

Drawing a line between such squares means that the corresponding

flanges are rigidly attached to each other.

By convention in this library, the connector characterized as a

filled grey square is called flange_a and placed at the

left side of the component in the "design view" and the connector

characterized as a non-filled grey square is called flange_b

and placed at the right side of the component in the "design view".

The two connectors are completely identical, with the only

exception that the graphical layout is a little bit different in order

to distinguish them for easier access of the connector variables.

For example, J1.flange_a.tau is the cut-torque in the connector

flange_a of component J1.

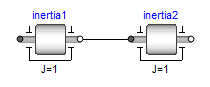

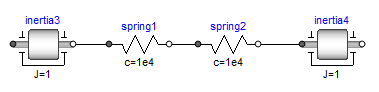

The components of this library can be connected together in an arbitrary way. E.g., it is possible to connect two springs or two shafts with inertia directly together, see figure below.

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.FlangeConnectors

Modelica.Mechanics.Rotational.UsersGuide.FlangeConnectorsA flange is described by the connector class Flange_a or Flange_b. As already noted in section Overview, the two connector classes are completely identical. There is only a difference in the icons, in order to easier identify a flange variable in a diagram. Both connector classes contain the following variables:

SI.Angle phi "Absolute rotation angle of flange"; flow SI.Torque tau "Cut torque in the flange";

If needed, the angular velocity w and the

angular acceleration a of a flange connector can be

determined by differentiation of the flange angle phi:

w = der(phi); a = der(w);

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.SupportTorques

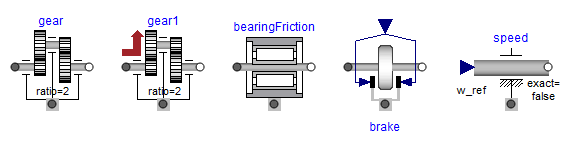

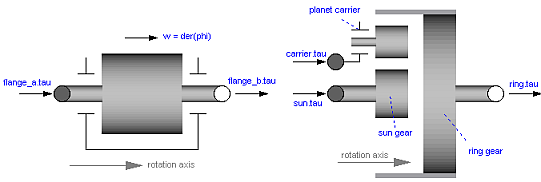

Modelica.Mechanics.Rotational.UsersGuide.SupportTorquesThe following figure shows examples of components equipped with a support flange (framed flange in the lower center), which can be used to fix components on the ground or on other rotating elements or to combine them with force elements. Via Boolean parameter useSupport, the support flange is enabled or disabled. If it is enabled, it must be connected. If it is disabled, it needs not be connected. Enabled support flanges offer, e.g., the possibility to model gearboxes mounted on the ground via spring-damper-systems (cf. example ElasticBearing).

Depending on the setting of useSupport, the icon of the corresponding component is changing, to either show the support flange or a ground mounting. For example, the two implementations in the following figure give identical results.

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.SignConventions

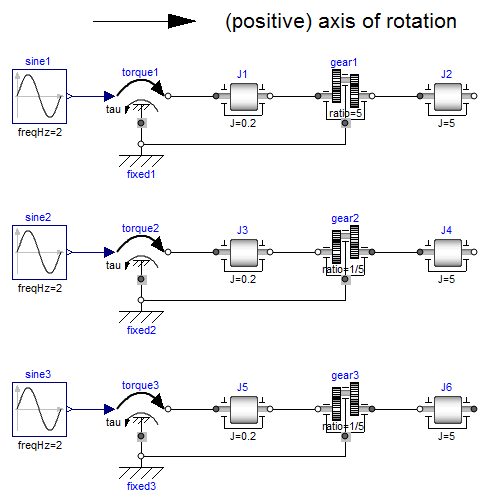

Modelica.Mechanics.Rotational.UsersGuide.SignConventionsThe variables of a component of this library can be accessed in the usual way. However, since most of these variables are basically elements of vectors, i.e., have a direction, the question arises how the signs of variables shall be interpreted. The basic idea is explained at hand of the following figure:

In the figure, three identical drive trains are shown. The only difference is that the gear of the middle drive train and the gear as well as the right inertia of the lower drive train are horizontally flipped with regards to the upper drive train. The signs of variables are now interpreted in the following way: Due to the 1-dimensional nature of the model, all components are basically connected together along one line (more complicated cases are discussed below). First, one has to define a positive direction of this line, called axis of rotation. In the top of the figure this is characterized by an arrow and a corresponding text. The simple rule is now: If a variable of a component is positive and can be interpreted as the element of a vector (e.g., torque or angular velocity vector), the corresponding vector is directed into the positive direction of the axis of rotation. In the following figure, the right-most inertias of the figure above are displayed with the positive vector direction displayed according to this rule:

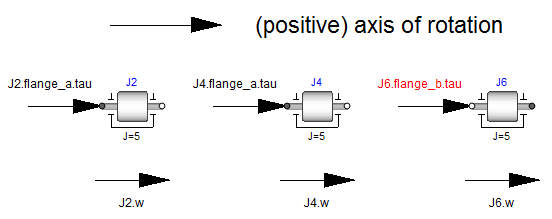

The cut-torques J2.flange_a.tau, J4.flange_a.tau and J6.flange_b.tau

of the right inertias are all identical and are directed into the

direction of rotation if the values are positive. Similarly,

the angular velocities J2.w, J4.w and J6.w of the right inertias

are all identical and are also directed into the

direction of rotation if the values are positive. Some special

cases are shown in the next figure:

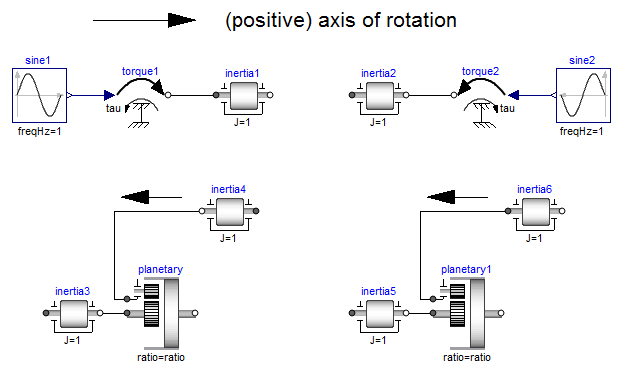

In the upper part of the figure, two variants of the connection of an

external torque and an inertia are shown. In both cases, a positive

signal input into the torque component accelerates the inertias

inertia1 and inertia2 into the positive axis of rotation,

i.e., the angular accelerations inertia1.a and inertia2.a

are positive and are directed along the "axis of rotation" arrow.

In the lower part of the figure the connection of inertias with

a planetary gear is shown. Note, that the three flanges of the

planetary gearbox are located along the axis of rotation and that

the axis direction determines the positive rotation along these

flanges. As a result, the positive rotation for inertia4 and inertia6

is as indicated with the additional black arrows.

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.UserDefinedComponents

Modelica.Mechanics.Rotational.UsersGuide.UserDefinedComponentsIn this section some hints are given to define your own 1-dimensional rotational components which are compatible with the elements of this package. It is convenient to define a new component by inheritance from one of the following base classes, which are defined in sublibrary Interfaces: Interfaces:

| Name | Description |

|---|---|

| PartialCompliant | Compliant connection of two rotational 1-dim. flanges (used for force laws such as a spring or a damper). |

| PartialCompliantWithRelativeStates | Same as "PartialCompliant", but relative angle and relative speed are defined as preferred states. Use this partial model if the force law needs anyway the relative speed. The advantage is that it is usually better to use relative angles between drive train components as states, especially, if the angle is not limited (e.g., as for drive trains in vehicles). |

| PartialElementaryTwoFlangesAndSupport2 | Partial model for a 1-dim. rotational gear consisting of the flange of an input shaft, the flange of an output shaft and the support. |

| PartialTorque | Partial model of a torque acting at the flange (accelerates the flange). |

| PartialTwoFlanges | General connection of two rotational 1-dim. flanges. |

| PartialAbsoluteSensor | Measure absolute flange variables. |

| PartialRelativeSensor | Measure relative flange variables. |

The difference between these base classes are the auxiliary variables defined in the model and the relations between the flange variables already defined in the base class. For example, in model PartialCompliant there is no support flange, whereas in model PartialElementaryTwoFlangesAndSupport2 there is a support flange.

The equations of a mechanical component are vector equations, i.e., they need to be expressed in a common coordinate system. Therefore, for a component a local axis of rotation has to be defined. All vector quantities, such as cut-torques or angular velocities have to be expressed according to this definition. Examples for such a definition are given in the following figure for an inertia component and a planetary gearbox:

As can be seen, all vectors are directed into the direction

of the rotation axis. The angles in the flanges are defined

correspondingly. For example, the angle sun.phi in the

flange of the sun wheel of the planetary gearbox is positive,

if rotated in mathematical positive direction (= counter clock

wise) along the axis of rotation.

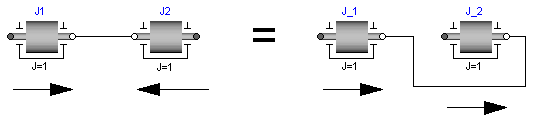

On first view, one may assume that the selected local coordinate system has an influence on the usage of the component. But this is not the case, as shown in the next figure:

In the figure the local axes of rotation of the components

are shown. The connection of two inertias in the left and in the

right part of the figure are completely equivalent, i.e., the right

part is just a different drawing of the left part. This is due to the

fact, that by a connection, the two local coordinate systems are

made identical and the (automatically) generated connection equations

(= angles are identical, cut-torques sum-up to zero) are also

expressed in this common coordinate system. Therefore, even if in

the left figure it seems to be that the angular velocity vector of

J2 goes from right to left, in reality it goes from

left to right as shown in the right part of the figure, where the

local coordinate systems are drawn such that they are aligned.

Note, that the simple rule stated in section

Sign conventions

also determines that

the angular velocity of J2 in the left part of the

figure is directed from left to right.

To summarize, the local coordinate system selected for a component is just necessary, in order that the equations of this component are expressed correctly. The selection of the coordinate system is arbitrary and has no influence on the usage of the component. Especially, the actual direction of, e.g., a cut-torque is most easily determined by the rule of section Sign conventions. A more strict determination by aligning coordinate systems and then using the vector direction of the local coordinate systems, often requires a re-drawing of the diagram and is therefore less convenient to use.

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.RequirementsForSimulationTool

Modelica.Mechanics.Rotational.UsersGuide.RequirementsForSimulationToolThis library is designed in a fully object oriented way in order that components can be connected together in every meaningful combination (e.g., direct connection of two springs or two inertias). As a consequence, most models lead to a system of differential-algebraic equations (DAE) of index 3 (= constraint equations have to be differentiated twice in order to arrive at a state space representation) and the Modelica translator or the simulator has to cope with this system representation. According to our present knowledge, this requires that the Modelica translator is able to symbolically differentiate equations (otherwise it is e.g., not possible to provide consistent initial conditions; even if consistent initial conditions are present, most numerical DAE integrators can cope at most with index 2 DAEs).

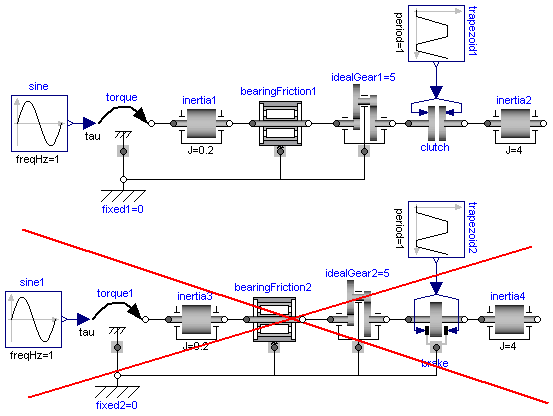

The elements of this library can be connected together in an arbitrary way. However, difficulties may occur, if the elements which can lock the relative motion between two flanges are connected rigidly together such that essentially the same relative motion can be locked. The reason is that the cut-torque in the locked phase is not uniquely defined if the elements are locked at the same time instant (i.e., there does not exist a unique solution) and some simulation systems may not be able to handle this situation, since this leads to a singularity during simulation. Currently, this type of problem can occur with the Coulomb friction elements such as BearingFriction, Clutch, Brake or LossyGear when the elements become stuck:

In the figure above, two typical situations are shown: In the upper part of

the figure, the series connection of rigidly attached bearingFriction1 and

clutch components are shown. This does not hurt, because the bearingFriction1

element can lock the relative motion between the element and the housing (fixed1),

whereas the clutch element can lock the relative motion between the two

connected flanges. On the contrary, the drive train in the lower part of the figure

may give rise to simulation problems, because the bearingFriction2 element

and the brake element can lock the relative motion between a flange and

the housing and these flanges are rigidly connected together, i.e.,

essentially the same relative motion can be locked. These difficulties

may be solved by either introducing a compliance between these flanges

or by combining the bearing friction and brake element into

one component and resolving the ambiguity of the frictional torque in the

stuck mode of that component. A tool may handle this situation also automatically,

by picking one solution of the infinitely many, e.g., the one where

the difference to the value of the previous time instant is as small

as possible.

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.StateSelection

Modelica.Mechanics.Rotational.UsersGuide.StateSelectionOnly a few components of the Rotational library use the der(…) operator and are therefore candidates to have states. Most important, component Inertia defines the absolute rotation angle and the absolute angular velocity of this component as candidate for states. In the "Advanced" menu the built-in StateSelect enumeration can be set to define the priority to use these variables as states. Without further action, in most cases a tool will select these variables as states.

For positioning drive trains where the goal is to position a load (e.g. the drive train of a robot, or of an elevator), the absolute angles of the components are bounded, and the issue discussed below is not present.

For drive trains where the goal is to control the velocity of a load (e.g. the drive train of a vehicle or the crank angle of an engine), the absolute angles of the components are quickly increasing during operation. This is critical, because then the step size control of time integrators might no longer work appropriately.

Integrators with step size control adjust their time step size automatically to meet user defined error bounds ("tolerances"). Typically the local error estimate ESTi is compared with a mixed bound for absolute and relative errors.

EST_i ≤ abstol_i + reltol_i*|x_i|

Here, abstoli and reltoli denote the bounds for the absolute and relative error of state variable xi, respectively. This mixed error bound is used since it is more robust than a pure relative error based error bound if the nominal value xi is (very) close to 0. In a Modelica simulation model, typically the same relative tolerance reltol is used for all states and the absolute tolerances are computed using the relative tolerance and the nominal values of the states:

reltol_i = reltol abstol_i = reltol*x_i(nominal)*0.01

This error control fails if the state variable xi grows without bounds (such as for a drive train or the crank angle of a vehicle), since then the allowed error also grows without bounds. The effect is that the error control on this variable is practically switched off. The correct way to handle this would be to set reltoli = 0 on such a state variable and only use an absolute tolerance for the step size control.

At the time of the library design, there was not yet a possibility to provide this information in Modelica. In order to reduce this effect, it is advisable to not use absolute angles, but relative angles as states. A user can define relative variables as states explicitly with component RelativeStates. Furthermore, all compliant components, such as SpringDamper are defining the relative angle and the relative angular velocity as preferred states. Therefore, a tool will select in most cases relative angles as states.

The relative angles of compliant components are usually small. For example, the deformation of a typical elastic component is in the order of 1e-4 rad. Without further action, the error control would not work properly on variables that are so small (so often switching the error control off). The remedy is to define explicitly a nominal value on the relative angle. This definition is provided in the "Advanced" menu of the compliant components with parameter "phi_nominal". The default value is 1e-4 rad, to be in the order of a compliant deformation of a drive. For some components, like a Clutch, this might be too small and a value of phi_nominal = 1 rad might be more appropriate (a value of phi_nominal = 1e-4 rad does not hurt, but just makes the error control unnecessarily stringent).

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.ModelingOfFriction

Modelica.Mechanics.Rotational.UsersGuide.ModelingOfFrictionSeveral elements of this library model Coulomb friction with the method proposed in:

The friction equations are defined in base model Interfaces.PartialFriction. In the following, there are given explanations.

Assume first the most simplest friction problem: A block sliding on a surface.

The friction force f acts between the block surface and the environment surface and

shall be a linear function of the relative velocity v between the two surfaces.

When the relative velocity becomes zero, the two surfaces are stuck to each other and

the friction force is no longer a function of v. The element starts sliding

again if the friction force becomes larger than the maximum static friction force

f0 (indicated by f0 in equations below).

This element could be defined with a parameterized curve description leading

to the following equations:

forward = s > 1;

backward = s < -1;

v = if forward then s-1 elseif backward then s+1 else 0;

f = if forward then f0 + f1*(s-1) elseif

backward then -f0 + f1*(s+1) else f0*s;

This model completely describes the simplified friction element in a declarative way. Unfortunately, currently it is not known how to transform such an element description automatically in a form which can be simulated:

The block is described by the following equation:

m*der(v) = u - f

Note, that m is the mass of the block and u(t) is the given driving force. If the element is in its "forward sliding" mode, that is s ≥ 1, this model is described by:

m*der(v) = u - f

v = s - 1

f = f_0 + f_1*(s-1)

which can be easily transformed into state space form with v as the state. If the block becomes stuck, that is -1 ≤ s ≤ 1, the equation v = 0 becomes active and therefore v can no longer be a state, that is an index change takes place. Besides the difficulty to handle the variable state change, there is a more serious problem:

Assume that the block is stuck and that s becomes greater than one. Before the event occurs, s ≤ 1 and v = 0; at the event instant s > 1 because this relation is the event triggering condition. The element switches into the forward sliding mode where v is a state which is initialized with its last value v = 0. Since v is a state, s is computed from v via s := v + 1, resulting in s = 1, that is the relation s > 1 becomes false and the element switches back into the stuck mode. In other words, it is never possible to switch into the forward sliding mode. Taking numerical errors into account, the situation is even worse.

The key to the solution is the observation that v = 0 in the stuck

mode and when forward sliding starts, but der(v) > 0 when sliding

starts and der(v) = 0 in the stuck mode. Since the friction characteristic

at zero velocity is no functional relationship, again a parameterized curve description

with a new curve parameter sa (denoted also sa below)

has to be used leading to the following equations (note: at zero velocity):

startFor = sa > 1;

startBack = sa < -1;

a = der(v);

a = if startFor then sa-1 elseif startBack then sa+1 else 0;

f = if startFor then f0 elseif startBack then -f0 else f0*sa;

At zero velocity, these equations and the equation of the block form a mixed continuous/discrete set of equations which has to be solved at event instants (e.g. by a fix point iteration), When switching from sliding to stuck mode, the velocity is small or zero. Since the derivative of the constraint equation der(v) = 0 is fulfilled in the stuck mode, the velocity remains small even if v = 0 is not explicitly taken into account. The approach to use the acceleration der(v) = 0 as "constraint" instead of v = 0, is often used in multi-body software. The benefit is that the velocity v remains a state in all switching configurations (there is a small, linear drift, but the friction element would have to stay stuck several days before the drift becomes too large). Consequently, v is small but may have any sign when switching from stuck to sliding mode; if the friction element starts to slide, say in the forward direction, one has to wait until the velocity is really positive, before switching to forward mode (note, that even for exact calculation without numerical errors a "waiting" phase is necessary, because v = 0 when sliding starts). Since der(v) > 0, this will occur after a small time period. This "waiting" procedure can be described by a state machine. Collecting all the pieces together, finally results in the following equations of a simple friction element:

// part of mixed system of equations

startFor = pre(mode) == Stuck and sa > 1;

startBack = pre(mode) == Stuck and sa < -1;

a = der(v);

a = if pre(mode) == Forward or startFor then sa - 1 elseif

pre(mode) == Backward or startBack then sa + 1 else 0;

f = if pre(mode) == Forward or startFor then f0 + f1*v elseif

pre(mode) == Backward or startBack then -f0 + f1*v else f0*sa;

// state machine to determine configuration

mode = if (pre(mode) == Forward or startFor) and v>0 then Forward elseif

(pre(mode) == Backward or startBack) and v<0 then Backward else Stuck;

The above approach to model a simplified friction element is slightly generalized in model Interfaces.PartialFriction:

Extends from Modelica.Icons.Information (Icon for general information packages).

Modelica.Mechanics.Rotational.UsersGuide.References

Modelica.Mechanics.Rotational.UsersGuide.References| [Pelchen2002] | Pelchen C., Schweiger C., and Otter M.: "Modeling and Simulating the Efficiency of Gearboxes and of Planetary Gearboxes". 2nd International Modelica Conference, pp. 257–266, Germany, 2002 |

Extends from Modelica.Icons.References (Icon for external references).

Modelica.Mechanics.Rotational.UsersGuide.Contact

Modelica.Mechanics.Rotational.UsersGuide.ContactFor current information on library officers please refer to the main Contact section.

Extends from Modelica.Icons.Contact (Icon for contact information).

Automatically generated Thu Oct 1 16:07:55 2020.