LossyGearDemo1Example to show that gear efficiency may lead to stuck motion |

|

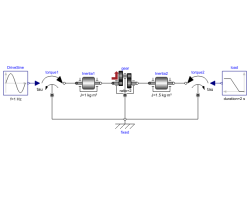

Diagram

Information

This information is part of the Modelica Standard Library maintained by the Modelica Association.

This model contains two inertias which are connected by an ideal gear where the friction between the teeth of the gear is modeled in a physical meaningful way (friction may lead to stuck mode which locks the motion of the gear). The friction is defined by an efficiency factor (= 0.5) for forward and backward driving condition leading to a torque dependent friction loss. Simulate for about 0.5 seconds. The friction in the gear will take all modes (forward and backward rolling, as well as stuck).

You may plot:

Inertia1.w,

Inertia2.w : angular velocities of inertias

powerLoss : power lost in the gear

gear.mode : 1 = forward rolling

0 = stuck (w=0)

-1 = backward rolling

Note, powerLoss (= sum of the power flows of the connectors) and

gear.powerLoss (= gear.tau_loss*gear.w_a,

where gear.tau_loss is determined in a non-trivial way

from the stuck/sliding situation of the bearing and teeth friction;

= equation (16) in [Pelchen2002])

should be identical, or the difference should be close to zero, if model

LossyGear

is correctly implemented.