Calculation of the mean convective heat transfer coefficient kc for a helical pipe in the laminar flow regime.

There are basically three differences:

The critical Reynolds number Re_crit in a helical pipe depends on its mean curvature diameter d_coil . The smaller the mean curvature diameter of the helical pipe, the earlier the turbulent regime will start due to vortexes out of higher centrifugal forces.

The mean convective heat transfer coefficient kc for helical pipes is calculated through the corresponding Nusselt number Nu according to [VDI 2002, p. Gc 2, eq. 5] :

Nu = 3.66 + 0.08*[1 + 0.8*(d_hyd/d_coil)^0.9]*Re^m*Pr^(1/3)

with the exponent m for the Reynolds number

m = 0.5 + 0.2903*(d_hyd/d_coil)^0.194

and the resulting mean convective heat transfer coefficient kc

kc = Nu * lambda / d_hyd

with

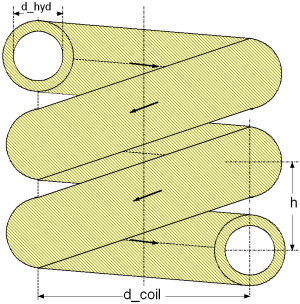

| d_mean | as mean diameter of helical pipe [m], |

| d_coil = f(geometry) | as mean curvature diameter of helical pipe [m], |

| d_hyd | as hydraulic diameter of the helical pipe [m], |

| h | as slope of helical pipe [m], |

| kc | as mean convective heat transfer coefficient [W/(m2K)], |

| lambda | as heat conductivity of fluid [W/(mK)], |

| L | as total length of helical pipe [m], |

| Nu = kc*d_hyd/lambda | as mean Nusselt number [-], |

| Pr = eta*cp/lambda | as Prandtl number [-], |

| Re = rho*v*d_hyd/eta | as Reynolds number [-], |

| Re_crit = f(geometry) | as critical Reynolds number [-]. |

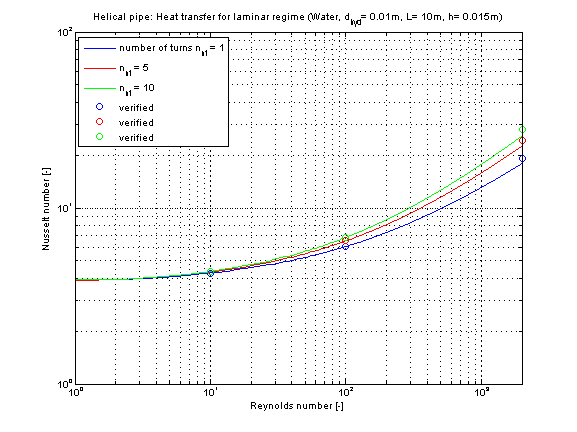

The mean Nusselt number Nu representing the mean convective heat transfer coefficient kc is shown below for different numbers of turns n_nt at constant total length of the helical pipe.

The convective heat transfer of a helical pipe is enhanced compared to a straight pipe due to occurring turbulences resulting out of centrifugal forces. The higher the number of turns, the better is the convective heat transfer for the same length of a pipe.

Note that the ratio of hydraulic diameter to total length of helical pipe d_hyd/L has no remarkable influence on the coefficient of heat transfer kc .