AIMC_InverterAsynchronous induction machine with squirrel cage and inverter |

|

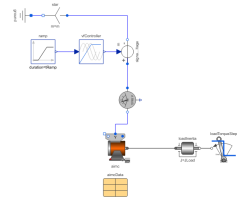

Diagram

Information

This information is part of the Modelica Standard Library maintained by the Modelica Association.

An ideal frequency inverter is modeled by using a VfController and a three-phase SignalVoltage. Frequency is raised by a ramp, causing the asynchronous induction machine with squirrel cage to start, and accelerating inertias. At time tStep a load step is applied.

Simulate for 1.5 seconds and plot (versus time):

- currentQuasiRMSSensor.I: stator current RMS

- aimc.wMechanical: motor's speed

- aimc.tauElectrical: motor's torque

Parameters (8)

| VNominal |

Value: 100 Type: Voltage (V) Description: Nominal RMS voltage per phase |

|---|---|

| fNominal |

Value: aimcData.fsNominal Type: Frequency (Hz) Description: Nominal frequency |

| f |

Value: fNominal Type: Frequency (Hz) Description: Maximum operational frequency |

| tRamp |

Value: 1 Type: Time (s) Description: Frequency ramp |

| TLoad |

Value: 161.4 Type: Torque (N·m) Description: Nominal load torque |

| tStep |

Value: 1.2 Type: Time (s) Description: Time of load torque step |

| JLoad |

Value: 0.29 Type: Inertia (kg·m²) Description: Load's moment of inertia |

| aimcData |

Value: Type: AIM_SquirrelCageData |

Components (11)

| aimc |

Type: AIM_SquirrelCage |

|

|---|---|---|

| currentQuasiRMSSensor |

Type: CurrentQuasiRMSSensor |

|

| ramp |

Type: Ramp |

|

| vfController |

Type: VfController |

|

| signalVoltage |

Type: SignalVoltage |

|

| star |

Type: Star |

|

| ground |

Type: Ground |

|

| loadInertia |

Type: Inertia |

|

| loadTorqueStep |

Type: TorqueStep |

|

| terminalBox |

Type: TerminalBox |

|

| aimcData |

Type: AIM_SquirrelCageData |